The Third Angle

Best Business Podcast (Gold), British Podcast Awards 2023

How do you build a fully electric motorcycle with no compromises on performance? How can we truly experience what the virtual world feels like? What does it take to design the first commercially available flying car? And how do you build a lightsaber? These are some of the questions this podcast answers as we share the moments where digital transforms physical, and meet the brilliant minds behind some of the most innovative products around the world - each powered by PTC technology.

The Third Angle

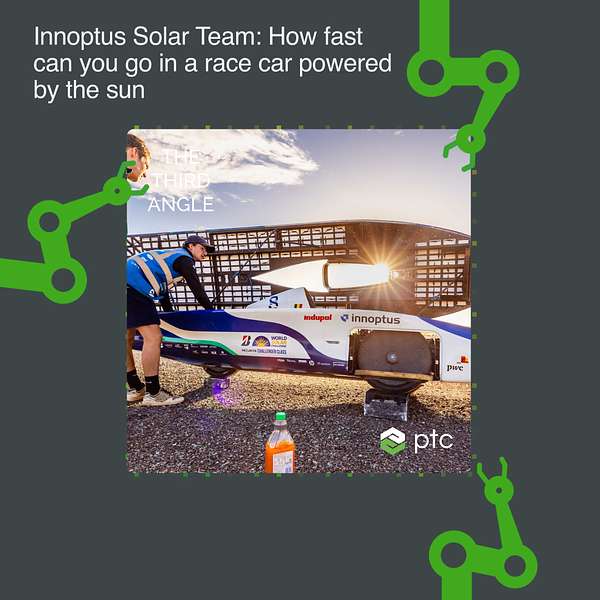

Innoptus Solar Team: How fast can you go in a race car powered by the sun?

“We try to test new things… our solar cells that we used 5 years ago are now the solar cells on your roof.”

In 2004, a group of Belgian engineering students built a solar car to compete in the World Solar Challenge, a 3021km endurance race through the Australian Outback. Twenty years later, the Innoptus Solar team is still going strong, with new students coming together to build new solar racing cars. They are sponsored by PTC Partner Innoptus (part of the 4ITEGO Group) and take part in races all over the world.

For the team, success is all about collaboration and innovation, constantly refining the design of their car to make it faster and more efficient. They are currently double World Champions with their tenth solar car, the Infinite. Clever features like the fin at the back of the car improve aerodynamics and give them an extra bit of help from the wind, and a motor which has been optimised to 98% efficiency helps them to go faster. It is also a fantastic development opportunity for the students involved, with them being able to gain the equivalent of 5 years of development experience in 1 year, as well as have the opportunity to work on a World Champion racing car.

Our producer Wederik De Backer went to the Innoptus Solar Team HQ in Leuven to meet two students who are part of the current team, Head of Engineering Jonas Vlamijnck and Mechanical Engineer Jasper Gutschoven. As well as explaining how they became involved and the level of dedication needed to win races, they give us a tour of their workspace and latest car.

Find out more about the Innoptus Solar Team here.

Find out more about Creo+ here.

Your host is Paul Haimes from industrial software company PTC.

Episodes are released bi-weekly. Follow us on LinkedIn and X for updates.

This is an 18Sixty production for PTC. Executive producer is Jacqui Cook. Sound design and editing by Clarissa Maycock. Location recording by Wederik De Backer. Music by Rowan Bishop.

Welcome to Third Angle, where you find us racing to the podium with solar power.

I’m your host, Paul Haimes from industrial software company PTC. In this podcast, we share the moments where digital transforms physical and meet the brilliant minds behind some of the most innovative products around the world, each powered by PTC technology. If you’re a regular listener to this podcast, you’ll know that I’m a big motor racing fan. But one race I’ve yet to have the privilege of seeing is the World Solar Challenge, first held in 1987, when it was won by the Sunraycer from General Motors. The current champions of that race are the Innoptus Solar team, founded 20 years ago by a team of engineering students from Leuven University. They set out to build the very first Belgian solar car, the Umicar One and took on the challenge of a 3,021 km endurance race through the Australian outback.

Today, and 10 solar cars later, they are sponsored by PTC partner Innoptus, who are part of the 4ITEGO Group and are at the top of their game, having won the last two world challenges. Teamwork, collaboration, and some very bright minds are key to their success, helping them come up with some innovative design and engineering features like the rotating fin that harnesses the power of the wind to help push the car along. We sent our producer to the team headquarters in Leuven, Belgium to meet the head of engineering Jonas, and mechanical engineer Jasper, two students who are part of the current team. They talk about the challenge involved with building and racing a solar car, what motivates them, and why they think their highly efficient solar-powered motor should get Elon Musk’s attention.

So I’m Jonas, I’m the head of mechanics from the Innoptus solar team. And I’m also a student studying industrial engineering. So, last year, around March, I applied to become a member of the solar team. It’s just an opportunity that you can get to work with another 12 members who are highly motivated also. And just the opportunity to work on a car itself. I’m very happy to be here right now.

So as you can see, it’s quite a long car, it’s like five metres long, quite small as well, only having three wheels. So today we are in our workshop from the Innoptus solar team. So it’s in the centre of Leuven. Here we work on the car, we build things, we assemble it, and everything is also stored here. We also have a room to work on more exotic things. It’s just an amazing place.

Hello, I’m Jasper, I’m 22 years old, and I’m a mechanical engineer on the Innoptus solar team. In 2019, I started my studying career in Leuven. And there was a big screen at the start of my career where the World Solar Challenge was on the live feed from the team. It blew my mind how it worked. It became a goal to be part of the team. That was my main purpose during my studies to study hard to be part of the team. It brings so much joy in doing it, and so much experience. The learning curve in the solar team is amazing. I’ve learned so much more than I’ve learned over my studies in the past four years. Bringing everything that you’ve studied into practice is something that you don’t always get in studies. We’ve got labs, but this is real stuff in the real world. And being able to do that here is so great.

In 2004, there was a documentary on national television about the Solar Challenge in Australia. And there were some students from the campus group in Leuven who thought yes, we want to do that as well. So they started to assemble a team to ask for permission from the university. So there it started. And over the years, every two years there was a new car built. In the beginning, it’s quite a challenge to even finish a Solar Challenge. The car wasn’t reliable enough. So after a few years, we started building a more reliable car. If you look at our achievements and our positions where we finished races, we started climbing in the ranks, we came fifth, third, then second. And then in 2019, we came first for the first time. And now we try to be unbeaten. As a team, we mostly participate in two types of races. The main one where we build a car is the World Solar Challenge in Australia. And that’s a race where we drive as fast as possible 3,021 kilometres. We start at eight o’clock in the morning, and we drive till five o’clock in the afternoon. And at five o’clock, we stop and we camp at the side of the road, or where the car has stopped. So we do it as fast as possible – this year, we did it in four days and two hours. And then we have South Africa, an eight-day-long race. And each day, you can see it as a stage race. So in the end, it’s not the person who crosses the finish line first, but the person who did the most kilometres in those eight days.

So welcome to our workplaces in the centre of Leuven. So we’re going to take you on a little bit of a tour. So first of all, when you enter, you have quite a long hallway where we can park our cars and our trailer. So during working times, they’re just standing here, but when we go to events, we take them out like now, there’s a lot of room. Because we are having events later today.

This is what we call the dust cave. It’s where we do all our things that produce a lot of chemical dust, like sawing or cutting carbon fibre. So it’s an area where you don’t go in without protection due to health issues. And that’s why there is a dedicated room for it.

Also, you can see we have some fridges lying around. It’s always, “Why does the solar team have three fridges standing there, that’s quite a low temperature.” That’s to store our carbon fibre. So we are using pre-made carbon fibre to build our solar car. And to make sure that it doesn’t go bad, we need to store it at a very low temperature. So as you can see, there are just rolls and rolls with carbon fibre in them, and then we get those parts out through specific shapes. And then we make it into a mould, cure it in an oven, and then you get finished parts out of it. It gets very cold, it’s like minus 30 degrees. When you want to start working you first need to take it out and let it rest a little bit so we can handle it because otherwise you can lose your fingers, I would say. So if you go a little bit further, I think it’s the most beautiful view of our workplace. It’s actually completely open, we’ve got some office space to the right side, and then our cars in the middle. At this moment, there is only one car, our ninth solar car here, because our 10th is still coming back from a race. And I think we can go through that score. Because it’s the best piece of the whole workplace I would say. Without it, we wouldn’t be here.

It’s quite a challenge to get in. Now the car is open, so the possibility of getting in the car is much bigger. But when the solar panel is closed during a race, there is only a narrow gap to get into the car. There will be three centimetres where you have to push your body through. Pilots jump out of the car in less than 15 seconds. That is a safety requirement from the race organisation. But yes, I think every pilot is also capable of going into the car in less than 15 seconds and driving away.

So before we can get inside the car, there are quite a few things you need to do. You need to take everything out of your pockets and remove your watch, or any other things you have on you because they can damage the solar cells on the car. Another thing is you need to remove your normal shoes during the race. Sometimes we wear racing shoes, and those we can wear, but I don’t have them here. So I’m just in my socks. And then to get inside of the car, it’s quite a manoeuvre. First, you need to tilt the steering wheel up so you get a little bit more room. And then to get inside, you take the space that protects your head and shimmy yourself as low as possible to get the centre of gravity as low as possible, put the steering wheel down, put on your seatbelt, and then you can drive.

So to become a driver, there are quite a few challenges. First and foremost, you need to fit inside the car. That’s challenge one. Challenge two is you need to weigh less than 65 kilos. So getting below that is for some people impossible and for some still a challenge. A driver’s licence is necessary. And then quite a lot of motivation is required. Having good driving skills, being sporty, and having a good condition, because driving a car for four hours in Australia and in South Africa for only two hours, is still quite difficult. It’s quite hot, so you need to be prepared for those situations as well. So even our pilots have to train for that. And one amazing way we do that is we go to a sauna and we set up a simulator there and drive in the sauna in the simulator. Normally if you go to the sauna, you sit in there for like 15 minutes or so. We are driving inside the sonar for like a few hours to simulate race conditions. It’s quite an experience.

Yes, so when we were moving more to the back, there were the ends of the car, there is one more wheel, inside there is a motor, the motor is made by ourselves. It has an efficiency higher than 98%, which we are doing much better than the motors of Elon Musk. We are still waiting for an invitation from him, but it’s not coming. And there is our secret weapon, the weapon that was introduced in 2022 in South Africa, it’s what we call the fin. The fin creates a sailing effect when we drive the car, a sailing effect of the wind, where we get an extra push from the wind. So that fin is now collapsed in the car. But with the push of a button, it comes out of the car. So the extension of the fin can be compared with the sail of a sailboat. But it’s also an extra amount of stability, because it’s still a static fin, so the fin cannot really rotate. But in 2023, we introduced a rotating fin, so we can optimise the angle of the fin to the angle of the wind where it’s coming from. And with that, we won the Innovation Award at the Bridgestone World Solar Challenge in 2023. And that’s something that our team strives to win, that innovation award, every year. I think we have won it now four times or three times. At the end of the car, there is also a licence plate. The licence plate is necessary because we drive on public roads during our race. And on that licence plate, there is also a camera. And that’s because we don’t have side mirrors to look behind us. But we look behind us with a camera. The side mirrors are a bit… we don’t have them due to the high amount of drag it will introduce. Actually, a fun fact we always say that the amount of drag that our car produces is equal to the amount of drag that the side mirror of a normal car produces.

The car weighs, with a battery, and without a driver 170 kilogrammes. So a gust of wind can take the car off the road, and it sometimes happens during the race. Fortunately, this didn’t happen with us in 2023. But we had a spin in 2019 where there was literally a professional race driver in our car driving at that moment. The car was picked up by what we call a “wheely-wheely”, it’s a small tornado that is very local. The car spun two times and luckily landed back in its tyres, so we could still drive – but that could happen during the race.

Hi, I’m Xavier Werbrouck, CEO of 4ITEGO Group, which is the group on top of Innoptus and Infinite. Infinite gave the name to the new car, and Innoptus is the main sponsor.

The car is important, first of all, because we are in a complete energy transition, and we definitely need to make sure that innovation is driving our future. But on the other hand, what is important to me is that we support students, who will be the entrepreneurs of the future. Let’s say we are baptising them as the entrepreneurs of the future. What is also important is the way we are doing knowledge transfer from team to team. It’s really special because every 12 months, a lot of knowledge needs to be transferred. This is something that in a company typically is not every 12 months, so we need to be more efficient in that way for our solar team so we can bring a kind of stability because we are long-term partners. So we have knowledge from year over year over year, but the way they handle, as a student team, the knowledge transfer, I can say that a lot of companies could learn a lot about how to transfer knowledge inside the company. If we want to grow our business, we continuously need new people in the company. And there are a lot of people in our company with 10, 15, 20 years of experience. But these younger people are also bringing a new spirit into the company.

So we already use a case for companies, we try to test new things like solar panels that are not on the market yet. But as a team, we see these technologies, after we test them, get implemented in the market. So our solar cells that we fused five years ago are now the solar cells on your roof. And as well with our motor that is so efficient, we think that these types of motors will be mass produced in the future within five years.

I think one of the lessons you can take from it is that working together is very important. And when you design, listen to people who have done it before you. Because sometimes you have ideas but they have done or had the same idea maybe before you and they can tell you if it’s still a good idea or you should change something because sometimes in your mind, one thing seems very good but maybe you need to look in another direction. So getting feedback from them is the most important thing from all our 20 years of building a solar car.

Try to dream big, don’t be afraid to try to achieve something big. Elon Musk, call us.

That was Jonas and Jasper from the Innoptus solar team. Looking towards next season and aiming for more success, the team is giving the car and innovation facelift with technical optimizations using PTC’s Creo+, the SaaS-based version of Creo, PTC’s 3D CAD solution. Time to meet our expert Brian Thompson, who heads up PTC’s CAD division. Brian, we spoke about Creo before, but can you give our listeners a high-level overview of what Creo+ offers and how the adopter solar racing team will be able to benefit from it?

The first great thing about Creo+ that this team will notice is the administrative burden is almost completely eliminated. So all you need is valid credentials into PTC’s Atlas platform and entitlement for Creo+ assigned to you and you are good to go. It’s a matter of just logging into Atlas and saying yes, I’d like to run Creo, and you’re running Creo five minutes later, it really is fantastic. And so the first thing that they will notice is their ability to bring new members on to the team is going to be really, really simplified. It’s going to be so easy for them to get new users up and running. Because we administer everything from PTC’s cloud platform. There are no more licence files to manage, and no more worrying about installation, we deploy the technology to the students’ machines automatically directly from the cloud. So really, really fantastic improvement in licence administration. But let’s face it, the real challenge with the Innoptus solar team is the fact that this is a highly optimised, highly engineered vehicle that is literally world-class in terms of its performance. That takes very, very tight collaboration amongst various experts on the team that have specialities like mechanical design, maybe computational fluid dynamics, and so forth. And this is where the second significant benefit of Creo+ comes into play. We now have a much more dynamic collaboration environment for design engineers who are working on the same assembly – like, say, an entire solar car assembly – and the working methods with Creo+ allow for an entire team to work on the same design all at the same time to see one another’s updates dynamically as those updates are made. And to make sure in fact that no one is working on the same data at the same time, but to also allow them to collaborate very, very dynamically – much more dynamically than they would if they were manually checking the information in and out of Windchill. Which is effective, but we find that students who grew up with technology, have a predisposition to want to work highly dynamically, and highly interactively. And in fact, that’s exactly the way Creo+ was built. So this highly dynamic, highly interactive environment that we have with our collaboration environment with Creo+ is going to really serve the Innoptus team really well and make them even more effective than they obviously already are.